3D printing is a revolutionary technology that has made it possible to produce complex and intricate products from a digital design on a computer. Here’s a guide that explains what 3D printing is:

- 3D printing, also known as additive manufacturing, is a process of creating three-dimensional objects from a digital file.

- It involves building up layers of material to create a physical object, rather than removing material from a larger piece as in traditional manufacturing methods.

- 3D printers can work with a range of materials, including plastics, metals, and even food and human tissue.

- The technology has revolutionized the manufacturing industry, allowing for faster and more cost-effective production of prototypes and customized items.

- 3D printing has also found applications in a range of industries, from healthcare to aerospace.

- To start 3D printing, you need a 3D model created using computer-aided design (CAD) software or downloaded from an online platform.

- This 3D model is then sliced into thin layers and sent to the printer, which builds the object layer by layer until it is complete.

Importance of 3D printing in different industries

The aerospace industry was the first to adopt 3D printing, as it allowed them to create lightweight components at a fraction of the cost of traditional manufacturing processes. 3D printing has also found applications in the healthcare industry, where it is used to develop custom prosthetics, implants, and even organs.

Dental prostheses, inlays, and implants are some of the most popular 3D-printed items in the medical sector. The automotive industry uses 3D printing to create prototypes, heat exchangers, and clamping fixtures. 3D printing has also brought changes to the field of architecture, where it allows for easy and affordable creation of intricate models.

The jewelry industry uses 3D printing to create molds, and in the fashion industry, it has been used to create custom-designed accessories.

The possibilities of 3D printing are huge and are only limited by the creativity of those who use it.

| 3D Printing Technology | Popularity Percentage |

|---|---|

| Material Extrusion | 39% |

| Vat Polymerization | 22% |

| Powder Bed Fusion | 18% |

| Material Jetting | 11% |

| Binder Jetting | 6% |

| Directed Energy Deposition | 3% |

| Sheet Lamination | 1% |

Binder Jetting

Binder Jetting is a 3D printing process that uses a binding liquid to selectively join powder material together to form a 3D part. Here are the steps to help you get started with binder jetting:

- Choose the right binder: The type of binder used depends on the type of powder or system that is being used or customer application requirements.

- Spread powder material: The powder material is spread over the build platform using a roller.

- Deposit binder adhesive: The print head deposits the binder adhesive on top of the powder where required.

- Lower the build platform: The build platform is lowered by the model’s layer thickness.

- Spread another layer of powder: Another layer of powder is spread over the previous layer.

- Form the object: The object is formed where the powder is bound to the liquid.

- Post-processing: Additional post-processing can be performed to add significant time to the overall process.

Binder jetting has advantages, including the ability to make parts in a range of different colors and use a range of materials such as metal, polymers, and ceramics. It is faster than other 3D printing methods, and the two-material method allows for many different binder-powder combinations and various mechanical properties. However, it may not be suitable for structural parts due to the use of binder material.

Directed Energy Deposition

If you’re curious about Directed Energy Deposition (DED) as a 3D printing process, keep reading! Here’s a step-by-step guide to help you understand DED and how it works.

First things first: DED is a more complex 3D printing process that can be used to repair or add additional material to existing components. This technology is often used for industrial applications such as repairing turbine blades or propellers that have been damaged.

Here are the five steps involved in using DED as a 3D printing process:

- Create a 3D model. As with any 3D printing technique, the design of a part begins with the creation of the 3D model.

- Cut into Layers. The part is then cut into a multitude of layers representing the various layers of material needed to form the piece.

- Deposition of Material. DED involves depositing material onto a base or component that is being repaired through a nozzle mounted on a multi-axis arm.

- Melting of Material. The metal material that is fed to the nozzle is either provided in powder or wire form. A heat source melts the material at the same time as it is deposited, using a laser, electron beam, or plasma arc.

- Repeat Layers. The procedure is done repeatedly until the layers have solidified and created or repaired an object.

Overall, DED processes are primarily applicable to the printing and repair of large industrial metal structures and components, especially for the aerospace sector, but can also be used to produce robust lightweight composite parts.

Material Extrusion

Material Extrusion is a popular 3D printing process that uses a continuous thermoplastic or composite material filament to construct 3D parts. Here’s a simple guide on how to get started with Material Extrusion:

- Choose a filament material that meets your project needs. Thermoplastics like PLA, ABS, and Nylon are popular choices.

- Load the filament into the extruder on your 3D printer.

- Adjust the printer settings for temperature, speed, and layer thickness.

- Design your project with a 3D modeling software or find a pre-made design online.

- Generate a G-code file that your printer can read.

- Start the 3D print and monitor it closely for any issues.

- Once completed, remove the finished object from the printer and remove any support structures if necessary.

- Post-process the object if needed by smoothing or painting the surface.

Note that Material Extrusion has some disadvantages, such as poor part strength along the Z-axis and susceptibility to warping. However, it is easy to use and great for beginners. With the right materials and settings, you can produce high-quality 3D prints at home or for your small business.

Vat Polymerization

VAT polymerization technology is perfect for creating finely detailed objects with a smooth surface finish. It is great for jewelry, low-run injection molding prototypes, and dental and medical applications.

- Get a 3D printer that uses VAT polymerization technology, such as a stereolithography (SLA) printer or a Direct Light Processing (DLP) printer.

- Choose the right material. VAT polymerization 3D printers use a special UV-sensitive material called photopolymer resin.

- Prepare your design. Using software like AutoCAD or SolidWorks, create a 3D model that you want to print.

- Load the software onto the printer and connect it to your computer.

- Fill the vat with the photopolymer resin.

- The printer will shine UV light on specific areas of the resin, solidifying it and building the object layer by layer.

- After the printing is complete, remove the object from the vat and clean away any excess resin.

- Cure the object under UV light for better mechanical properties.

- Enjoy your 3D printed creation!

VAT polymerization is one of the most promising 3D printing technologies available today, offering high precision and overall quality. With a little bit of practice, you can become an expert at using VAT polymerization for your 3D printing needs!

Powder Bed Fusion

Pow Bed Fusion is a popular 3D printing method used in industrial additive manufacturing. If you’re interested in using Powder Bed Fusion for your projects, here’s a simple guide to get you started:

- Choose the right material: Powder Bed Fusion can work with both metals and polymers, but not all materials are compatible. Make sure you select a material that is suitable for the technique.

- Prepare the build surface: The process involves spreading a thin layer of powder across a build surface. You’ll need to ensure that the build surface is clean and level.

- Set your parameters: PBF processes depend on a wide range of variables including laser or beam power, spot size, hatch pattern, layer height, powder quality, and more. Make sure you set your parameters correctly before you start printing.

- Print your design: Once everything is set up, you can start printing your design. The process involves selectively melting or sintering powdered material using a laser beam or an electron beam.

- Postprocess your print: Postprocessing varies depending on the material and powder bed fusion process. In some cases, additional finishing operations such as bead blasting, tumbling, or dyeing may be required.

Remember, like any printing process, Powder Bed Fusion requires practice and experimentation before you can achieve your desired results.

Sheet Lamination

Sheet Lamination is a type of 3D printing that uses thin sheets of material stacked and laminated together to create a 3D object. If you are new to this technology, here are some steps to guide you on how to use Sheet Lamination for your 3D printing needs:

- Choose the right material. Sheet Lamination can work with a wide variety of materials, such as paper, plastic, metal, and woven fiber composites, each using different binding methods. Decide which material best suits your needs.

- Select the appropriate method. Sheet Lamination can be subdivided into groups based on the build material used, forming methods employed, and lamination technique used to bond the sheets together. Choose the method that will produce the best quality parts based on your requirements.

- Follow the process. To start the process, a thin sheet of material is fed from the roller or placed onto the build platform. Depending on the type of Sheet Lamination, the next layer may or may not be bonded to the previous sheet. This process is continued until the full height is achieved, and then the unwanted outer edges are removed to reveal the printed 3D object.

- Enjoy the benefits. Sheet Lamination is a low-cost and fast method for creating prototypes and functional parts. It is environmentally friendly and suitable for small businesses and home and hobby use. With the right material and method selection, Sheet Lamination can produce parts with desirable qualities, such as property gradients and engineered material properties for increased performance.

Material Jetting

Material Jetting is a popular 3D printing technology that is used to create detailed and functional prototypes that are close to the final model. Here is a how-to guide to help you understand Material Jetting better.

1. What is Material Jetting 3D printing?

Material Jetting is an additive manufacturing process that operates in a similar fashion to 2D printers.

2. How does Material Jetting 3D printing work?

The process of MJ 3D printing involves heating the liquid resin to 30-60°C to ensure optimal printing viscosity. Then, the printhead deposits hundreds of tiny droplets of photopolymer onto the build platform. The UV light source cures the deposited material solidifying it and creating the first layer of the part. After the layer is complete, the build platform moves downwards one layer height, and the process repeats until the whole part is complete.

3. What are the characteristics of Material Jetting 3D printing?

MJ is one of the most accurate 3D printing technologies. MJ systems have a tolerance of ± 0.1% with a typical lower limit of ± 0.1 mm. Warping is less common as printing happens at near room temperature.

4. What are the advantages of Material Jetting 3D printing?

MJ offers accurate multi-material and multi-color prints that represent end-use products. MJ allows different printheads to dispense different materials, which makes the creation of complex structures straightforward and widely used. MJ is also suitable for producing detailed and functional prototypes.

5. What are the limitations of Material Jetting 3D printing?

The main limitation of MJ is its smaller build volume, which makes it impossible to manufacture large-format parts. As with most other technologies, the process requires printing media and a post-processing step.

Overall, Material Jetting is a beneficial technology that is suitable for creating complex structures.

Which 3D printing technology is the cheapest?

| 3D Printing Technology | Cost per Cubic Foot |

|---|---|

| Material Extrusion | $50 – $200 |

| Vat Polymerization | $500 – $1,000 |

| Powder Bed Fusion | $1,000 – $5,000 |

| Material Jetting | $1,000 – $5,000 |

| Binder Jetting | $500 – $3,000 |

| Directed Energy Deposition | $500 – $1,000 |

| Sheet Lamination | $50 – $200 |

When it comes to 3D printing technology, cost is a major consideration for many businesses. The cheapest of the established 3D printing technologies is Material Extrusion or Fused Deposition Modeling (FDM).

FDM uses thermoplastic filaments, such as ABS or PLA, which are relatively cheap and widely available. FDM 3D printers are also the most accessible, with hobbyist-level printers starting at around $200.

However, FDM has the lowest resolution and accuracy compared to other technologies and is not the best option for printing complex designs or parts with intricate features. For businesses looking for a higher level of precision,

Stereolithography (SLA) and Selective Laser Sintering (SLS) are more expensive options. The cheapest SLS 3D printers start at around $5000, while SLA printers can cost around $4000-$5000.

It’s worth noting that cheap 3D printing doesn’t always mean low-quality results, but it’s important to choose the right technology for your specific application and budget.

What 3D printing technology is suitable for small businesses?

Small businesses often have limited resources and may be hesitant to invest in expensive equipment or technologies. Luckily, there are 3D printing technologies available that are affordable and suitable for small businesses.

Material Extrusion, also known as Fused Deposition Modeling (FDM), is the most common and affordable 3D printing technology. This process uses a spool of filament that is melted and extruded layer by layer to create a physical object.

FDM technology is easy to use, offers a variety of materials, and can produce functional prototypes or low-volume production parts. Another option for small businesses is Binder Jetting, which uses a liquid binder to bind together layers of powder material to create a solid object.

This technology is ideal for creating small, intricate parts at a low cost. Both Material Extrusion and Binder Jetting are suitable for small businesses as they are affordable, easy to use, and offer a range of materials to choose from.

By incorporating 3D printing into their operations, small businesses can save time and money on prototyping and production.

Which 3D printing technology is the most environmentally friendly?

One of the most important considerations for many businesses and individuals interested in 3D printing is sustainability. While all 3D printing technologies have the potential to be more environmentally friendly than traditional manufacturing methods, some are better than others. Here are some of the most environmentally friendly 3D printing technologies:

- Binder Jetting: This technology uses a liquid binder to bond layers of powder together. It is known for producing minimal waste and using less material than other technologies.

- Vat Polymerization: This technology uses a photopolymer resin that solidifies when exposed to light. It requires less material than other technologies and produces less waste.

- Powder Bed Fusion: This technology melts powdered material layer by layer, producing less waste than traditional manufacturing methods.

- Sheet Lamination: This is one of the most eco-friendly 3D printing technologies because it uses paper or other biodegradable materials as the raw material. It produces very little waste and is also one of the cheapest 3D printing technologies available.

While all of these technologies offer environmental benefits, it’s important to remember that sustainability is also determined by the materials used and the way the technology is used. By choosing the right 3D printing technology and materials, businesses and individuals can minimize their environmental impact and help create a more sustainable future.

Which 3D printing technology is the most promising?

According industry experts, the most promising 3D printing technology today is Binder Jetting. This technique involves selectively depositing a binding agent onto a powdered material bed, layer by layer, until the object is formed.

The final product needs to be sintered to achieve its required strength and density. Binder Jetting can create parts with higher accuracy and finer detail than other techniques like FDM.

It also offers a range of materials such as sand, ceramics, and metal matrix composites, making it a versatile option for different applications. Additionally, Binder Jetting is available at a lower cost than other industrial 3D printing technologies, making it an appealing choice for small businesses looking to adopt 3D printing.

The technology has already been utilized in aerospace, automotive, and medical industries, and it is expected to have a significant impact on the future of manufacturing and production.

What 3D printing technology is suitable for home and hobbies?

When it comes to 3D printing technology suitable for home and hobbies, Material Extrusion (FDM/FFF) stands out as an affordable and easy-to-use option.

FDM/FFF printers use a solid filament that is melted by a heated extruder, which then lays down layer after layer of material to form the object. With modern advancements like heated beds and enclosures, FDM/FFF 3D printers are even more accessible and user-friendly.

If you’re just getting started with 3D printing as a hobby, investing in an FDM/FFF printer can be a great option. These printers are widely available and come in different shapes and sizes, making it easy to find one that fits your budget and needs.

Additionally, FDM/FFF printing materials like PLA, ABS, PETG, and others are widely available and affordable, making it easier to experiment with different materials and designs.

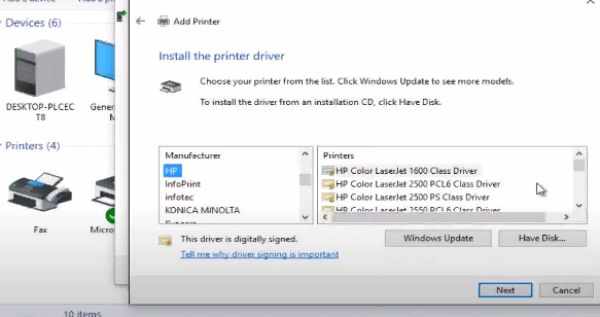

Do I have to have special knowledge to do 3D printing?

To get started with 3D printing, you don’t need extensive technical knowledge. The basics of 3D printing, such as how the machine works and how to add material, straightforward and easy to learn.

The 3D models can be downloaded from the internet and imported into the printer’s software for conversion into machine instructions. The software can do most of the work for you, taking care of the conversion process and guiding you every step of the way.

In most cases, adding material to the machine’s hopper or reservoir and pressing print is all it takes to get started.

However, if you’re designing parts from scratch, it’s important to understand DFM (Design For Manufacturing) principles for 3D printing, as well as some basic CAD (Computer-Aided Design) skills. With experience, you can move on to more advanced techniques and materials.

Overall, 3D printing is accessible and easy to learn for beginners.