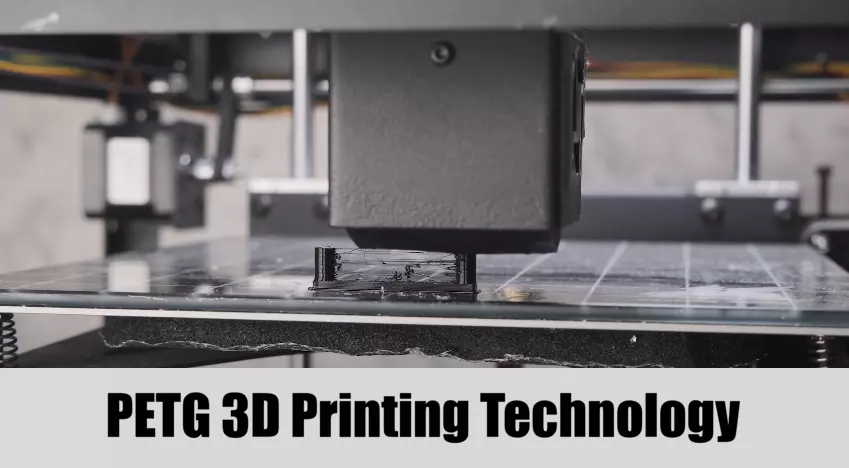

PETG 3D printing technology is a type of FDM printing that uses a modified version of Polyethylene Terephthalate (PET) to produce high-quality, durable prints.

PETG is known for its ease of printability, with good impact resistance and a glossy surface finish that is resistant to moisture, chemicals, and heat. The material also benefits from great thermal characteristics, allowing the plastic to cool efficiently with almost negligible warpage.

To ensure the best print quality, 3D printers using PETG should have a heated build platform and adjusted retraction settings to reduce stringing and oozing.

PETG 3D printing has become popular for a diverse range of applications, from the prototyping of consumer product packaging to manufacturing tools and aids, testing components, or even end-use parts such as snap fits and living hinges.

The use of PETG also extends beyond 3D printing, with its applications in industries ranging from dentistry to textiles, and in products such as bottles, cosmetics, and fabrics. Users should follow the manufacturer’s recommendations to achieve optimal results with PETG.

Printing temperature

PET filament is becoming increasingly popular due to its durability, chemical resistance, and low shrinkage. To achieve the best 3D prints with PETG, it’s important to adjust the 3D printer settings properly.

The optimal printing temperature range is typically 220-260°C, and the best printing speed falls between 40-60mm/s for standard 3D printers.

The nozzle temperature should be set to around 240°C and the bed temperature should be set to 80°C. It’s crucial to properly prepare the print bed by using a suitable surface, such as blue painter’s tape or a textured build surface like a powder-coated PEI sheet.

PETG has excellent bed adhesion, which can be good and bad as sometimes parts can become stuck to the print bed. To avoid over-adhesion, it’s recommended to use glue stick or hairspray on smooth surfaces. Likewise, bed leveling and nozzle calibration are crucial steps to ensure good quality prints.

Cost

PETG 3D printing is a popular form of 3D printing that uses a thermoplastic material known as Polyethylene terephthalate glycol, which is also known as PETG.

The cost of PETG 3D printing filament ranges from $23 to $40 per kilogram, depending on the brand and specifications.

PETG is a food-safe plastic material that is known for its strength and durability, making it suitable for 3D printing functional parts like gears and mechanical parts. PETG has a minimal shrinkage rate, and it is stronger than ABS. The cost of PETG 3D printing filament is affected by various factors that include raw material costs, filament tolerance, quantity, and brand/manufacturer. PETG 3D printing is a cost-effective option for printing quality parts that require strength and durability.

Overall, the cost of PETG 3D printing is relatively affordable, and it is a practical option for industrial and personal use.

Application

- Food packaging: PETG is FDA approved for food contact and is resistant to chemicals and moisture, making it a popular choice for food packaging.

- Prosthetics and medical equipment: PETG can be sterilized without compromising its properties, making it suitable for use in the medical industry.

- Aligner material: PETG’s flexibility and durability make it ideal for use as an aligner material in dentistry.

- Machine parts and tooling: PETG’s heat and chemical resistance make it a great option for creating durable end-use parts for machines, as well as tooling and testing components.

- Consumer packaging: PETG’s strength and durability make it an ideal choice for consumer packaging, especially for items that may be subjected to rough handling or transportation.

- Household items: PETG can be used to create a variety of household items, such as utensils and sports bottles, due to its resistance to chemicals and heat.

- Functional prototypes: PETG’s ease of use and ability to create strong parts make it a great option for functional prototypes in various industries.

- Reinforced PETG: PETG can be reinforced with materials such as carbon fiber and aramid fibers to increase its strength and stiffness, making it suitable for more demanding applications.

- Educational and DIY projects: PETG’s relative affordability and ease of use make it ideal for educational and DIY projects, such as creating custom phone cases or toy figurines.

- Sustainable applications: PETG is 100% recyclable with the same chemical composition as PET, making it an eco-friendly option for creating various objects and reducing waste.

Benefits of PETG printing

PETG Filament is an Excellent Choice for 3D Printing:

- PETG filament is made out of PET, a thermoplastic that has a greater strength and durability compared to other 3D printing materials.

- It is more flexible than other thermoplastics, which prevents it from becoming brittle when printed.

- PETG is 100% recyclable, making it an eco-friendly option for 3D printing.

- Its high viscosity is ideal for printing intricate designs and structures that require high precision and accuracy.

PETG Filament Offers Better Physical Properties:

- PETG is water, chemically, and fatigue-resistant, making it a preferred choice for industrial applications.

- It is more durable than PLA, less stiff, and has excellent thermal stability.

- PETG is stronger than PLA and more flexible than ABS, which makes it a popular material in the 3D printing community.

- With its excellent physical properties, PETG filament is suitable for printing translucent, shatter-resistant items like phone cases.

PETG Filament Offers Cost-Effective Printing:

- PETG filament is denser than PLA and has a melting point similar to that of PLA, making it an ideal replacement for PLA.

- It is a more cost-effective alternative to other popular 3D printing materials like TPU and ABS.

- PETG is odorless during printing, unlike ABS, which emits a noticeable odor.

PETG Filament is Recyclable:

- PETG filament is 100% recyclable, and its polymer chains are recoverable for future use.

- PETG can be recycled and re-used as a gas barrier for solvents and alcohol.

- It is important to check with a local recycler for their rules and regulations on what can be recycled.

MakeShaper’s High-Quality PETG Filament:

- MakeShaper’s PETG filaments are created using high-purity raw materials with superb extrusion every time in every project.

- The filaments are available in a dozen colors and two diameters.

- MakeShaper’s filaments are made in the USA, ensuring high-quality performance for all your 3D printing needs.

PETG 3d printing disadvantages

- Poor Bed Adhesion: One of the major disadvantages of PETG 3d printing is the issue of poor bed adhesion. This means that the material may not stick properly to the print bed, leading to poor print quality and even failure of the print. PETG requires a heated print bed and a slow print speed to ensure good adhesion.

- Warping: PETG also has a tendency to warp during printing, especially if the ambient temperature is too high. This can lead to the formation of gaps and deformations in the printed object. The issue of warping can be resolved by using a powerful cooling fan and ensuring proper print bed temperature.

- Stringing and Oozing: PETG has a tendency to produce stringing and oozing during printing. Stringing occurs when the extruder nozzle leaves thin strands of plastic between different parts of the object. Oozing occurs when the material oozes out of the nozzle when printing is paused or the extruder is moved to a new location. To solve this issue, users can reduce the printing temperature and adjust the retraction settings.

- Slow Printing Speed: PETG requires a slower printing speed compared to other 3d printing filaments such as PLA. This is because the material needs more time to melt and flow smoothly through the nozzle. A slower printing speed can result in longer printing times.

- Higher Printing Temperature: PETG requires a higher printing temperature than other filaments. This can be a disadvantage for some 3d printers, as not all printers can reach the required temperature. If the printer does not have a high enough maximum temperature, it will not be able to print with PETG.

- Difficulty in Post-Processing: PETG is difficult to process post-printing. It is harder to sand and paint, compared to other 3d printing filaments. The glossy surface of PETG can also make it difficult to adhere to certain types of paints.

- Price: PETG is generally more expensive than PLA and ABS, which can limit its affordability for some users. The higher cost can be attributed to the added glycol in the material, which enhances its durability and aesthetic appeal.

Best alternatives

PCTG

PCTG is a great alternative to PETG since it offers increased toughness, impact strength, and clarity. This filament is FDA certified and chemical resistant, which makes it perfect for printing medical devices and water bottles. PCTG has higher chemical resistance, a larger range of printing temperatures, and increased durability than PETG.

ABS

Acrylonitrile butadiene styrene or ABS is a versatile 3D printing filament that offers excellent strength and durability. ABS is perfect for printing items like toys, phone cases, and automotive parts. However, ABS releases fumes when heated, which can be toxic. Therefore, it is crucial to ensure appropriate ventilation when using ABS.

Nylon

Nylon is a strong and flexible filament that is perfect for printing durable items like gears and mechanical parts. This filament is also resistant to wear and tear, making it ideal for printing items that undergo constant friction. Nylon filament is relatively challenging to print since it requires higher temperatures to melt the plastic.

Polycarbonate

Polycarbonate is a tough and transparent filament that can withstand high temperatures and impact. This filament is ideal for printing items that require high strength and durability, such as automotive parts, safety equipment, and electronic components. Polycarbonate is relatively difficult to print and requires high temperatures, but it provides excellent results.

TPU

Thermoplastic polyurethane or TPU is a flexible and rubber-like filament that is perfect for printing items that require flexibility and elasticity. TPU is ideal for printing phone cases, toys, and other items that require rubber-like properties. TPU filament is relatively easy to print, but it requires specific printer adjustments to avoid extrusion problems.