Are new to the world of 3D printing? Are you wondering what materials to use to bring your designs to life?

Well, look no further than PLA, or polylactic acid, one of the most widely used plastics in the sector. Invented in 1930, PLA is a biodegradable thermoplastic that is sourced from natural and renewable resources such as corn starch, sugar cane, and tapioca roots.

Due to its eco-friendly origins, PLA has become popular in 3D printing, with its use spreading to a wide variety of industries and applications.

We’ll dive deep into PLA, its production and characteristics, its ease of use, and its behavior when used as a 3D printing material. So sit back, relax, and get ready to learn all about PLA for 3D printing!

PLA (polylactic acid) for 3D printing technology

Here are some tips on how to get started with PLA for 3D printing:

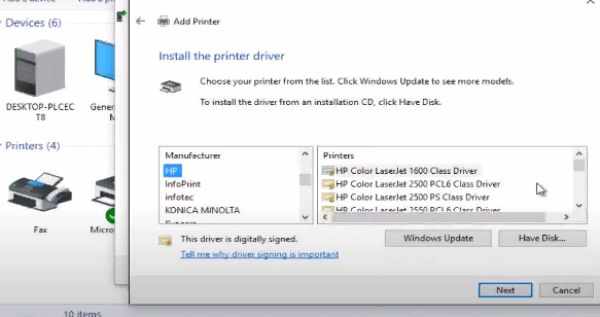

- Choose the right printer: PLA is a popular material for FDM (fused deposition modeling) 3D printers. Make sure your printer can achieve a suitable temperature range for PLA printing (180-220°C).

- Choose the right PLA filament: PLA filaments come in various colors and types. Look for filaments that are specifically designed for 3D printing and check the diameter compatibility with your printer’s extruder.

- Prepare your print bed: PLA has good adhesion properties, but a clean and level print bed is crucial for a successful print. Use tape or other adhesion aids if necessary.

- Adjust your printer settings: Start with the manufacturer’s recommended settings and adjust them according to your specific needs. Keep in mind that PLA prints at lower temperatures and doesn’t require a heated bed, which can save energy.

- Print and post-process: Start your print and monitor it closely. Once your print is finished, let it cool down before removing it from the print bed. Post-process as needed by sanding, polishing or painting.

- Consider the limitations: While PLA has many benefits, it’s important to know its limitations. PLA is not suitable for high heat applications and is less durable than other materials like ABS or PETG. Choose your applications accordingly.

By following these tips, you can start your 3D printing journey with PLA and create stunning prints that are both eco-friendly and cost-effective.

Benefits of PLA 3D printing

Polylactic Acid (PLA) is a popular material for 3D printing and offers several benefits over other materials. Here are some of the key advantages of using PLA for your 3D printing needs:

- Eco-Friendly: PLA is derived from natural sources like corn starch or sugar cane, making it a renewable and biodegradable material. Compared to petroleum-based plastics, PLA emits fewer greenhouse gases and requires less energy to produce, making it an eco-friendly option.

- Low Printing Temperature: PLA has a relatively low printing temperature compared to other thermoplastics, making it less likely to warp and clog the nozzle during printing. The material also produces better surface details and sharper features compared to other thermoplastics with higher melting temperatures.

- Ease of Use: PLA is one of the easiest material filaments to 3D print, thanks to its ability to adhere to a variety of surfaces and not requiring a heated print bed. Additionally, PLA does not emit smelly fumes when printed, making it a more pleasant material to work with.

- Range of Color Options: PLA is easily pigmented and comes in a diverse range of colors and blends. The material can also be mixed with wood, carbon, and even metal, while pigments can be added to achieve luminescent or glittery filaments.

- Easy Post-Processing: PLA prints are easily sanded, polished, and painted, allowing for an improved surface finish with relatively little effort. The material can also be drilled, milled, and glued, though care should be taken not to melt the part.

Disadvantages of PLA 3D printing

Here are some of the downsides to using PLA for 3D printing that you need to keep in mind:

- Limited Applications: PLA is not ideal for high-temperature applications as it has a low melting point. It may show signs of deformation or getting soft on a hot summer day, making it unsuitable for some projects.

- Moisture Sensitivity: PLA has a higher permeability than other plastics, which makes it more sensitive to moisture and oxygen. It can lead to faster food spoilage, making it unsuitable for long-term food storage.

- Recycling Challenges: PLA has a lower melting point and cannot be recycled with other plastics. This makes it difficult to recycle, and recycling PLA alone is not economically viable.

- Slow Decomposition: While PLA is compostable, it does not compost fast enough for industrial composters. The residue is not compost, and it doesn’t improve the quality of soil. The residue also changes the PH value of the soil, making it more acidic.

- Expensive: PLA is more expensive than fossil-based plastics, making it a less attractive option for some projects.

While PLA has its own set of disadvantages, it is still a popular material for 3D printing, especially for beginners. However, if you need to print objects for high-temperature applications or long-term storage, you may want to consider using other materials.

Best application for the 3D printing

- Rapid Prototyping: Prototyping is an essential step in product development, and 3D printing has made it faster and more cost-effective. With 3D printing, product designers can produce physical models of their designs quickly, enabling them to test and refine prototypes in the shortest amount of time.

- Product Customization: 3D printing technology has revolutionized the way businesses can customize their products. With 3D printing, companies can create customized designs and parts on demand without incurring high tooling costs.

- Medical Applications: 3D printing technology has proven to be a game-changer in the medical field, enabling healthcare professionals to create customized implants and prosthetics. The technology has also been used to create anatomical models that aid in surgical planning and medical education.

- Design: 3D printing has opened up new opportunities for designers. The technology has made it possible to create intricate and complex designs that were once impossible to create using traditional manufacturing methods.

- Education: 3D printing can be a powerful tool for education, allowing students to learn and experiment with technology. The technology can help students better understand concepts in science, engineering, and design.

Best alternatives

Looking alternative 3D printing filaments to bring your projects to life? Here are some of the best choices for 2023 based on factual data:

- Wound Up – Created by blending coffee grounds with conventional PLA, this unique filament allows makers to use their love for coffee to fuel their 3D printing projects.

- Conductive PLA – A composite of PLA plastic that is electrically conductive and contains carbon particles, this material is perfect for use in low-voltage circuits and touch devices.

- LayBrick – Made from sandstone and chalk, this hybrid filament gives 3D printed objects a stone-like appearance and texture.

- Hemp PLA – This filament is composed of fine particles of hemp mixed with a PLA polymer base, offering several advantages due to its natural properties, including being a biodegradable plastic that can be recycled or composted after use.

- Magnetic PLA – Made by mixing PLA with iron powder, this hybrid filament possesses metallic characteristics, allowing it to exhibit magnetic properties and grant a metallic appearance to the printed parts.

- Wood-Based Filaments – Using components such as cork and bamboo mixed with conventional PLA, these filaments offer a unique appearance and even emit a subtle wood scent.

- Fluorescent PLA – Bioplastics in fluorescent green produce sturdy and remarkable parts that glow in the dark.

These alternative 3D printing filaments offer a range of benefits including environmental sustainability, unique textures and appearances, and added functionality like magnetic or conductive properties.