Discover how to drill into concrete quicker. With an excellent hammer drill and concrete drill bits, making holes in concrete is nearly as simple as drilling in wood.

Best Tool For Drilling Concrete

Hammer drills vs. rotary hammers

Hammer drills and rotary hammers

Hammer drills and rotary hammers are both exceptional for drilling masonry. Rotary hammers are more powerful, however, and have a “hammer-only” mode with no rotation. They normally have an SDS chuck, which is much better for hammering.

Sure, you can drill a hole or more in a cinder block with a regular drill and a masonry bit, however you’ll wish to step it up a notch if you have an entire lot of holes to drill into 50-year-old concrete. In this story, we’ll give you the rundown on the differences in between a hammer drill and a rotary hammer, and help you figure out which tool is right for you. We’ll likewise show you some cool bits and devices and share some useful tips on how to get the most from these convenient tools.

Hammer drills and rotary hammers (likewise called rotary hammer drills) both produce a pounding force that makes them incredibly effective at blasting through masonry. As it spins, the bit chisels away at the masonry. The mechanical process that provides this pounding action is what separates the two tools.

A hammer drill has two discs that have ridges resembling the ridges on a poker chip. As one disc slides past the other, it rises and falls, triggering the chuck to slam forward and back. If there is no force on the chuck, the discs are separated by a clutch and the pounding action stops. This saves wear and tear. Many hammer drills can be used as a routine drill by turning off the hammering action.

A rotary hammer develops its pounding action with a piston owned by a crankshaft. The piston rides in a cylinder and produces atmospheric pressure when driven forward, and it’s the air pressure that really drives the hammer mechanism. Rotary hammers supply a lot more effect energy than hammer drills. They’re a lot more durable and are the preferred tool of the pros. Another huge benefit is that many rotary hammers have three settings: drill mode, hammer drill or simply hammer, so they can act like a tiny jackhammer. Of course, they cost more than a hammer drill, but more on that later on.

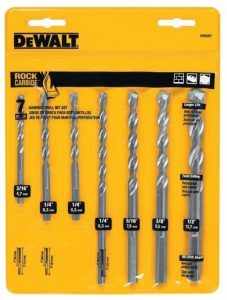

Hammer drill bits

Hammer drills are best for light masonry

A hammer drill works best at drilling holes in bricks, mortar and concrete blocks. But it can also deal with the occasional hole in put concrete.

You don’t need to spend tons of money on bits, but more costly bits are generally equipped with exceptional carbide pointers, and the tips are more firmly attached to the shank of the bits, which reduces damage in heavy use.

Rotary hammer bits and accessories

Rotary hammers are for bigger jobs

Rotary hammers excel at drilling holes in solidified concrete. They can likewise be fitted with all sorts of other attachments.

Rotary hammer accessories

Rotary hammer devices include a variety of chisels for scaling metal, breaking concrete, getting rid of tile and even digging hard soil. (The one on the left is for an SDS-Max chuck.) You can also add a three-jaw chuck for routine drill bits.

SDS-Plus chuck adapter

This adapter will permit you to use smooth-shank drill bits, hole saws and blending paddles. Simply remember to keep the setting on drill mode or you could damage the chuck.

The most popular type of chuck on the shelves at home centers today is the SDS-Plus. SDS-Plus bits have grooves on the shanks that lock securely into the chuck however permit the bit to return and forth individually of the chuck. They’re extremely easy to place and eliminate– no tools needed. A few of the actually huge rotary hammers have a comparable system, but bigger, called the SDS-Max. And there are a couple brands that have proprietary systems, so make sure the bit you purchase matches the tool you’re using.

When set to hammer mode, rotary hammers can be used for all sorts of jobs, and there are a lot of attachments to get those jobs done.

A few of the more popular attachments are shown in the image:

- Clay spade: Breaks up hard soil.

- Cold chisel: For busting up concrete.

- Tile eliminator: Works well for bring up ceramic tiles.

- Bull point sculpt: Used to begin holes in concrete.

- Scaling sculpt: Designed to eliminate rust, concrete and weld spatter.

If you currently own a rotary hammer and are searching for a durable drill to bore large holes in wood or mix joint compound, think about purchasing an SDS-Plus chuck adapter. This adapter will enable you to use smooth-shank drill bits, hole saws and blending paddles. Simply keep in mind to keep the setting on drill mode or you could destroy the chuck.

Which drill is right for you?

Some bits eat rebar

When you need to drill into strengthened concrete, purchase a bit that’s developed to chew through mesh wire and rebar along with concrete.

You can spend $50 on a hammer drill that will drill 1/2-in. holes in the majority of masonry, however investing more will get you two things: the capability to drill larger holes and– more important– faster drilling, which is excellent when you have lots of holes to drill.

The pounding power of a hammer drill is measured in BPM (beats/blows per minute). However the BPM ranking isn’t really the entire story: Motor amperage and how the drill feels in your hands are more important. All-metal chucks are more durable than ones with plastic parts. And while keyless chucks come in handy on a routine drill, they often don’t have the holding power required for drilling into masonry. Chuck size typically dictates the maximum suggested hole size the drill can handle.

The pounding power of a rotary hammer is measured in pounds of effect energy. When searching for rotary hammers, more amp power readies, but more effect energy is even more important. Rotary hammers are categorized by the maximum-size hole advised by the maker, however that does not indicate they can’t drill a larger hole every so often. If you require a drill for absolutely nothing but 7/8-in. holes, buy a bigger drill that won’t have to operate at its optimum capability all the time.

What You Get

$ 50 to $100 Hammer drills in this price range have motors with 6 to 8 amps. Helpful for drilling holes up to 1/2 in. in block, mortar, brick and other light masonry. These drills will likewise bore into concrete, but slowly.

$ 100 to $150 Hammer drills in this price range feature motors ranging from 7 to 10 amps. Helpful for drilling holes up to 5/8 in. in light masonry and concrete.

$ 150 to $225 In this price range, rotary hammers have motors that vary from 7 to 10 amps and deliver 1.5 to 3 ft.-lbs. of impact energy. Helpful for drilling holes in light masonry, and concrete approximately 1 in. Can also be used in hammer mode to get rid of mortar, bust small areas of concrete and sculpt tile.

Over $225 Rotary hammers in this price range provide an effect energy of over 10 ft.-lbs. and can drill 1-3/4- in. holes all day. They cost $400 to $800, however lease for about $60 daily.

Cordless

If you currently own cordless tools, inspect to see whether the same company makes a hammer drill or rotary hammer that works with the same batteries. Sometimes you can purchase a cordless tool without the battery cheaper than you can buy a corded one.

Drilling ideas

Clear the debris

The flutes on a drill bit are developed to bring up the debris from the hole as you drill, however the best method to clear the hole is to periodically pull the bit from the hole as you’re drilling. Less debris in the hole reduces friction, which suggests smoother drilling, less possibility of binding and longer-lasting drill bits.

Prevent overdrilling

Many hammer drills and rotary hammers are sold with a side manage and depth stop. Do yourself a favor and use them. There’s no need to burn up both time and bits by drilling deeper holes than you need to. And you don’t constantly want to drill all the method through a cinder block to its hollow core– some plastic anchors require a back to stop them or they will get pressed right through the hole.

Do not push too hard

There’s a “sweet spot” where the right rpm combined with the right pressure drills fastest. However you will not discover that sweet spot by lowering as hard as you can. In reality, excessive pressure will slow the drilling process and put a whole lot of unneeded wear and tear on the motor equipments. Plus, you’ll break bits.

Drill a smaller sized hole first

If you need to drill a couple holes that are bigger than the advised capability of your drill, begin with a smaller hole first. This will substantially reduce the load on the drill. Likewise, smaller bits do not skate around as much as bigger bits do, which is helpful when you require a hole in a precise spot.