Electric resistance heating is 100% energy effective in the sense that all the inbound electrical energy is converted to heat.

However, the majority of electricity is produced from coal, gas, or oil generators that transform just about 30% of the fuel’s energy into electrical energy. Since of electrical energy generation and transmission losses, electrical heat is frequently more expensive than heat produced in houses or services that use combustion home appliances, such as gas, propane, and oil heating systems.

If electrical energy is the only choice, heat pumps are more suitable in most environments, as they easily cut electrical power use by 50% when compared with electric resistance heating. The exception is in dry environments with either hot or blended (cold and hot) temperatures (these climates are discovered in the non-coastal, non-mountainous part of California; the southern tip of Nevada; the southwest corner of Utah; southern and western Arizona; southern and eastern New Mexico; the southeast corner of Colorado; and western Texas). For these dry environments, there are so couple of heating days that the high cost of heating is not economically considerable.

Electric resistance heating may likewise make sense for a home addition if it is not useful to extend the existing heater to provide heat to the new addition.

See also: Backup Generator for Your Home

TYPES OF ELECTRIC RESISTANCE HEATERS

Electric resistance heat can be supplied by central forced-air electric heating systems or by heating units in each space. Room heating systems can include electric baseboard heating systems, electric wall heaters, electric radiant heat, or electric area heating units. It is likewise possible to use electric thermal storage systems to avoid heating during times of peak power demand.

ELECTRIC FURNACES

Electric heating systems are more pricey to operate than other electric resistance systems because of their duct heat losses and the extra energy needed to distribute the heated air throughout your home (which is common for any heating system that uses ducts for distribution). Heated air is provided throughout the home through supply ducts and went back to the heater through return ducts. If these ducts run through unheated areas, they lose some of their heat through air leakage as well as heat radiation and convection from the duct’s surface area.

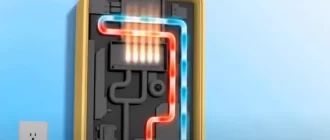

Blowers (large fans) in electrical heaters move air over a group of three to 7 electric resistance coils, called elements, each of which are normally rated at 5 kilowatts. The heater’s heating components trigger in stages to avoid straining the home’s electrical system. A built-in thermostat called a limitation controller avoids getting too hot. This limit controller might shut the furnace off if the blower fails or if a filthy filter is obstructing the air flow.

Similar to any furnace, it is essential to clean or change the heating system filters as advised by the producer, in order to keep the system operating at leading performance.

ELECTRIC BASEBOARD HEATERS

Electric baseboard heating systems are zonal heating systems controlled by thermostats located within each room. Baseboard heating systems include electric heating elements framed in metal pipes. The pipes, surrounded by aluminum fins to aid heat transfer, run the length of the baseboard heating system’s housing, or cabinet. As air within the heater is warmed, it rises into the space, and cooler air is drawn into the bottom of the heating system. Some heat is likewise radiated from the pipeline, fins, and real estate.

Baseboard heaters are generally set up below windows. There, the heating unit’s increasing warm air counteracts falling cool air from the cold window glass. Baseboard heaters are rarely situated on interior walls because basic heating practice is to supply heat at the home’s boundary, where the greatest heat loss happens.

Baseboard heating systems must sit at least three-quarters of an inch (1.9 centimeters) above the floor or carpet. This is to permit the cooler air on the floor to stream under and through the radiator fins so it can be heated up. The heating system should likewise fit securely to the wall to avoid the warm air from convecting behind it and streaking the wall with dust particles.

The quality of baseboard heating systems varies considerably. More affordable models can be noisy and frequently offer bad temperature level control. Try to find labels from Underwriter’s Laboratories (UL) and the National Electrical Producer’s Association (NEMA). Compare warranties of the various models you are thinking about.

ELECTRIC WALL HEATERS

Electric wall heating units consist of an electric element with a reflector behind it to reflect heat into the room and generally a fan to move air through the heater. They are usually set up on interior walls because installing them in an outside wall makes that wall challenging to insulate.

ELECTRIC THERMAL STORAGE

Some electric utilities structure their rates in a way just like telephone companies and charge more for electricity throughout the day and less in the evening. They do this in an effort to minimize their “peak” demand.

If you are a customer of such an utility, you might be able to take advantage of a heater that stores electrical heat during nighttime hours when rates are lower. This is called an electric thermal storage heater, and while it does not save energy, it can save you cash due to the fact that you can benefit from these lower rates.

The most typical kind of electrical thermal storage heating unit is a resistance heater with components enclosed in heat-storing ceramic. Central furnaces incorporating ceramic block are also available, although they are not as common as room heating systems. Saving electrically heated warm water in an insulated tank is another thermal storage option.

Some storage systems try to use the ground beneath houses for thermal storage of heat from electrical resistance cables. Nevertheless, this needs painstaking setup of insulation beneath concrete slabs and all around the heating elements to lessen significant heat losses to the earth. Ground storage likewise makes it difficult for thermostats to manage indoor temperatures.

Any type of energy storage systems suffers some energy loss. If you mean to pursue an electric thermal storage system, it would be best for the system to be located within the conditioned area of your home, so that any heat lost from the system actually warms your home, instead of leaving to the outdoors. It would also be best to understand how quickly heat will leave from the system. A system that leakages too much heat might cause control problems, such as the unexpected overheating of your home.

CONTROL SYSTEMS

All types of electrical resistance heating are managed through some kind of thermostat. Baseboard heating units often use a line-voltage thermostat (the thermostat directly controls the power supplied to the heating device), while other devices use low-voltage thermostats (the thermostat uses a relay to turn the device on and off). Line-voltage thermostats can be constructed into the baseboard heater, however then they often don’t sense the room temperature level properly. It’s best to instead use a remote line-voltage or low-voltage thermostat installed on an interior wall. Both line-voltage and low-voltage thermostats are readily available as programmable thermostats for instantly holding up the temperature in the evening or while you’re away.

Baseboard heating units supply heat to each space separately, so they are ideally fit to zone heating, which involves heating the occupied rooms in your home while allowing unoccupied area (such as empty visitor rooms or seldom-used rooms) to stay cooler. Zone heating can produce energy savings of more than 20% compared to heating both occupied and vacant areas of your house.

Zone heating is most efficient when the cooler portions of your home are insulated from the heated parts, allowing the different zones to truly run individually. Note that the cooler parts of your home still have to be warmed to well above freezing to prevent freezing pipelines.